Energy Information Administration (EIA): “Gross inputs to ADUs in April 2020 were 3.4 million barrels per day (b/d) (21%) lower than the five-year (2015–19) average, and gross inputs to ADUs in May 2020 were 3.6 million b/d (21%) lower than the five-year average (Figure 1).

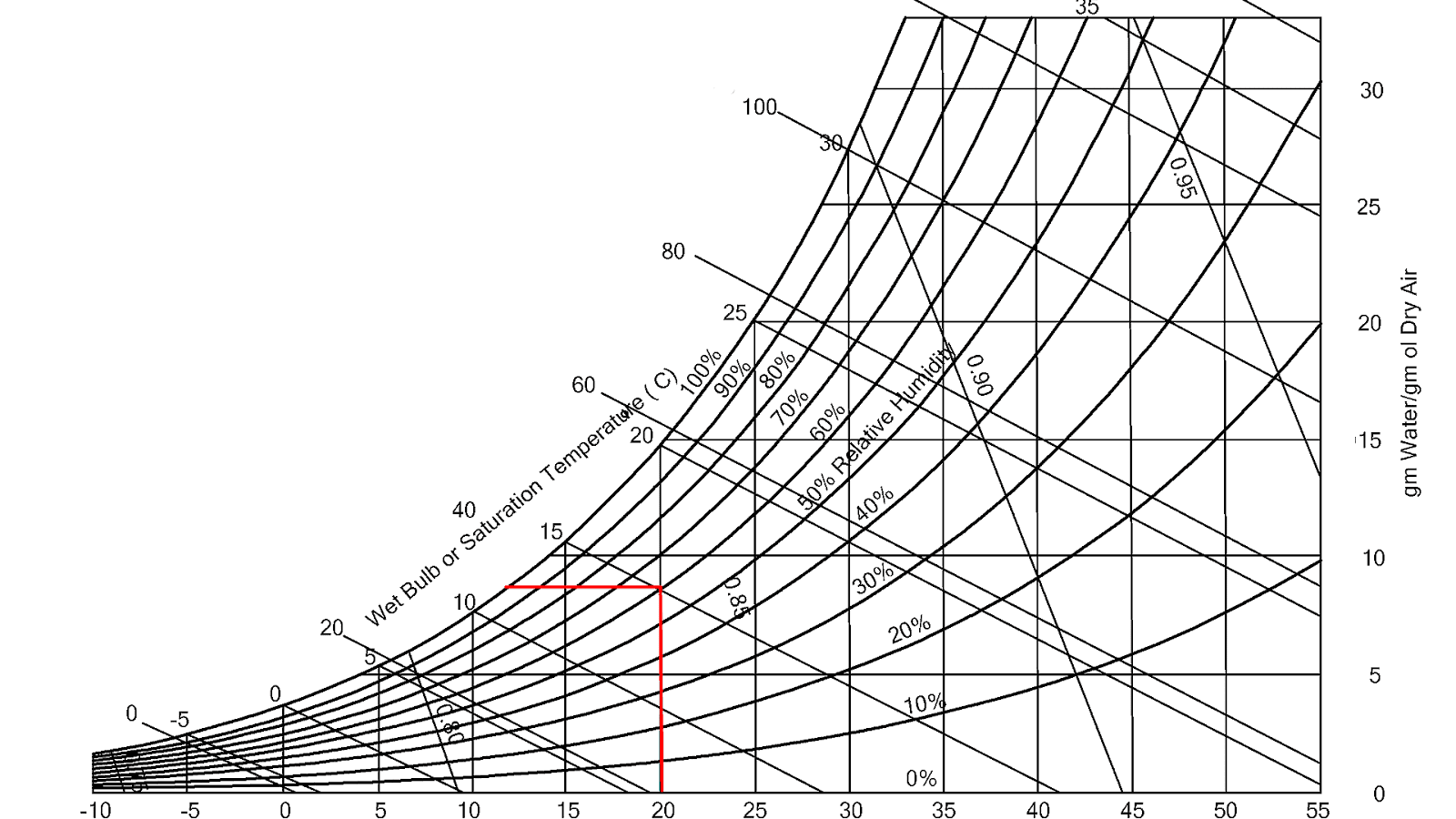

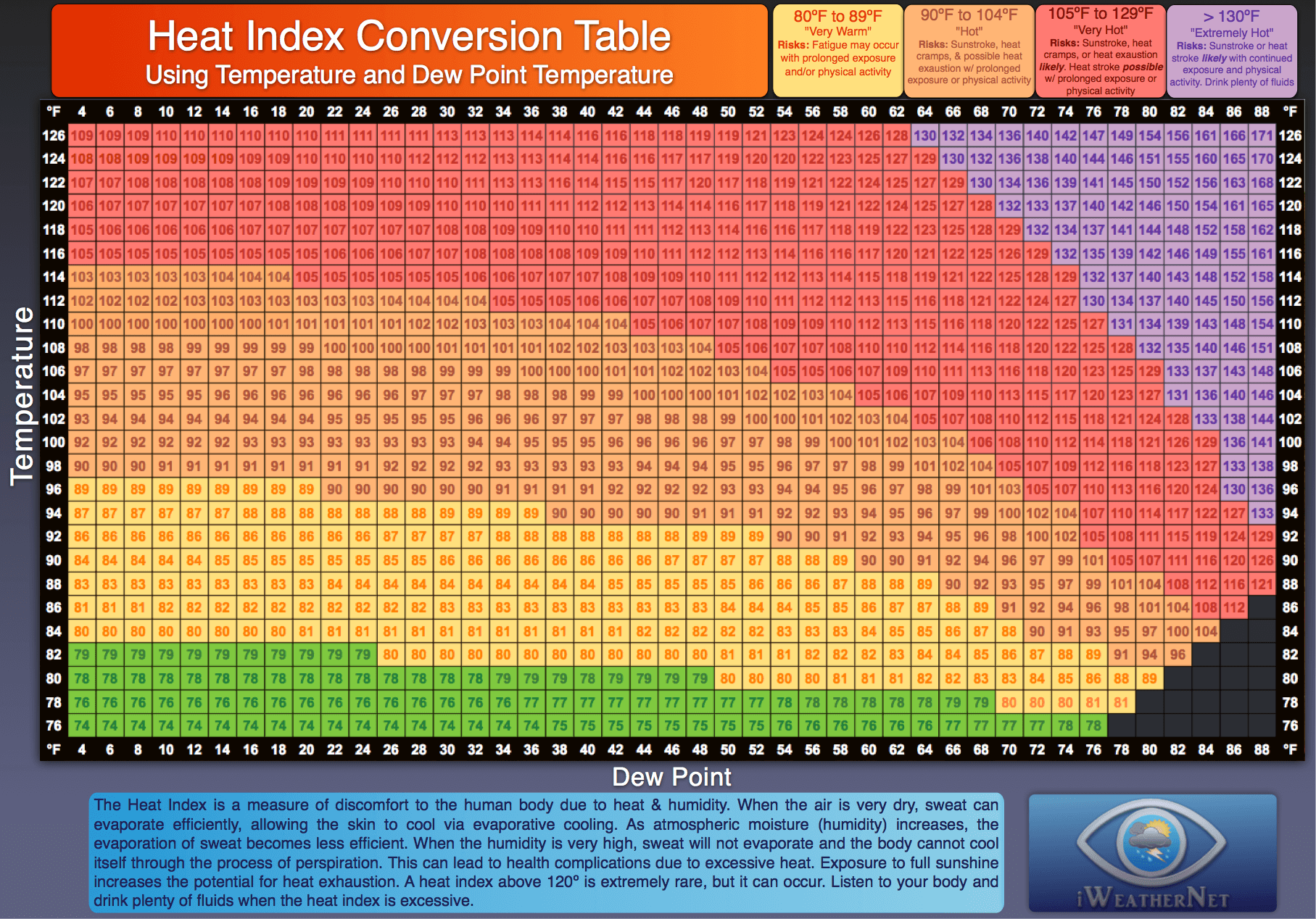

The oil and gas industry have responded to this lower demand by decreasing refinery runs, with the largest drops in units focused on gasoline production.Īccording to the U.S. Lower Throughputs, Higher Corrosion RisksĮver since COVID-19 gripped the world, consumers and businesses have reduced their consumption of transportation fuels. However, during turndown operation, such as what the industry is currently experiencing, the low temperature zone of the heaters – commonly referred to as the cold end – can approach the acid dew point temperature. This variable is easy to control during normal operating conditions. For heaters, the goal is to maintain the temperature of susceptible regions above that dew point. Several researchers have done extensive work on accurately estimating the acid dew point, or the temperature at which a certain acidic gas will condense into droplets. The amount of sulfur-bearing compounds, mostly in the form of hydrogen sulfide (H 2S) in the fuel, is directly correlated with the concentration of the acid droplets and, therefore, with the degree of corrosion. These condensed acids will corrode the tubes and other extended surfaces in convection sections, flue ducts, stacks, air preheater, etc. When fuels containing sulfurous compounds combust, the resulting flue gases can condense into sulfuric acid (H 2SO 4), sulfurous acid (H 2SO 3), and other aggressive substances.

Condensation and Corrosion in Refinery Equipment However, low-level flue gas heat recovery comes with its challenges, and one of the most important ones to keep in mind is flue gas dew point corrosion. One way to improve efficiency is to use low-level flue gas heat recovery, which is the process of exchanging heat of the flue gas with lower-temperature processes such as boiler feed water, combustion air, etc. With growing impetus to reduce carbon emissions, improving fired heaters’ efficiency is amongst the most impactful steps a refinery can make. For a typical refinery with a secondary processing facility, the average fuel consumption of fired heaters amounts to about 7 wt% of crude throughput. The utility system constituting boilers and gas turbines consumes about 30-40% of fuel. In refineries, fired heaters are among the leading users of energy, consuming about 40-50% of fuel in various process units.

For optimal safety and efficiency, refineries must monitor temperatures and make operational adjustments as necessary. However, this process could lead to the condensation of flue gases, and these acidic droplets can corrode equipment. Low-level flue gas recovery allows refineries to improve their heaters’ efficiency.

0 kommentar(er)

0 kommentar(er)